How to operate the plate oil filter correctly

Prior to use: Inspection and inspection of pressure type oil filter

1 check that the motor of the pressure type oil filter should be inspected regularly by the testing unit.

2 machine placement is stable, test rotation inspection can not swing, vibration.

3 check whether the connection is correct and firm, and the monkey hose hoop is applied to the joint between the hose and the metal tube, so as to prevent the oil pipeline from falling off in operation.

4 check whether the external power supply is correct, and the machine housing should be reliably grounded.

5 check whether the filter paper is dry and clean.

6 check whether the fire extinguishing equipment is in line with the requirements.

2. The use and attention of pressure type oil filter

1 during operation, check the oil pipe joints and valves of the oil filtration equipment regularly. If there is any fault, check and deal with it immediately. Anti static grounding measures shall be adopted for metal pipelines of oil filters and oil systems.

2 when the oil filter is shut down, the inlet valve of the oil pump should be closed first, then the outlet valve should be closed. The order is opposite when you start the machine.

3 during operation, every interface should be examined without leakage.

4 no smoke should be prohibited at the working site of the oil filter and no smoking should be allowed near the filter.

5. The operator must be strict with his work and be conscientious and responsible. He must not do anything irrelevant when he is on duty.

6 duty attendants should pay attention to entering, discharging and running of motor. The lack of phase operation is strictly prohibited.

7 abnormal sound or oil leakage during operation should be stopped immediately.

8 switch the power switch when moving position.

9 after the work is completed, cut off the power supply, clean up the site, and store the waste oil in the designated location without getting lost.

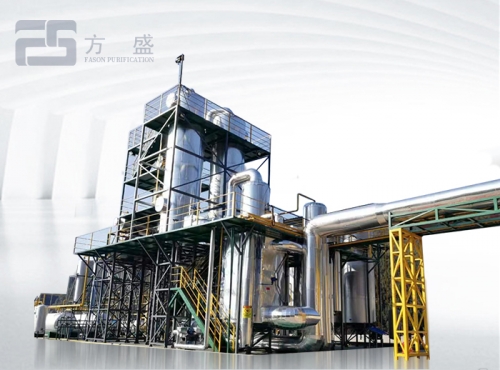

This equipment adopts the international advanced negative pressure distillation principle, which can be used in all kinds of waste oil in industrial production, and purify the waste oil to produce the regenerated base oil or diesel oil that conforms to the national standard. It is possible to extract 98% of the available oil from raw material waste oil, which has the characteristics of small pollution, fast speed, small occupying area, long service life and good quality of regenerated oil.

The electrical components of the whole machine adopt international first-class products such as Schneider and SIEMENS, which guarantee the quality and quality of the products. Large screen touch screen is used to display and control all kinds of temperature in production process, display pressure, control valve and other controllable devices.