1、 Scope of application

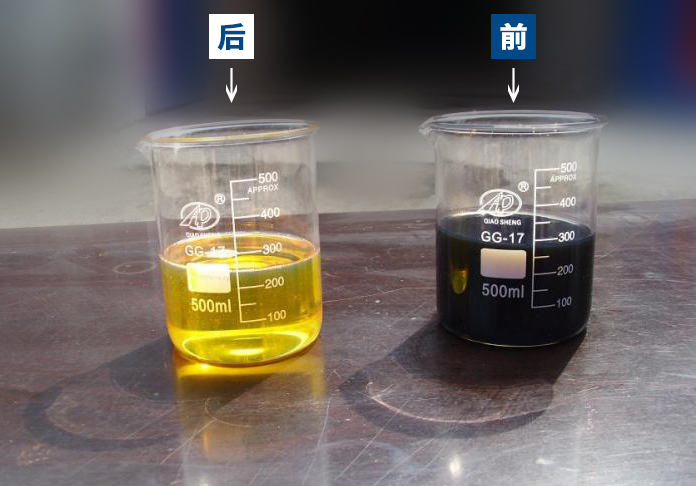

It is suitable for engine oil, gear oil (open and closed) hydraulic oil, forming oil, gutter oil, rail oil, compressor oil, vacuum pump oil, total loss system oil, axle oil, pneumatic tool oil, guide rail oil, bearing oil, etc Regeneration and purification of turbine oil, cylinder oil, drawing oil, conduction oil, transformer insulating oil (mineral type and synthetic type), heat transfer oil, quenching oil, insulating oil and rolling oil. It is especially suitable for large and small repair plants, general machinery, ships, trucks and other heavy pollution (i.e. dirty oil and mixed oil that cannot be treated by chemical methods). At the same time, it is also suitable for the production of biodiesel from waste plastic, waste tire and orange stalk.

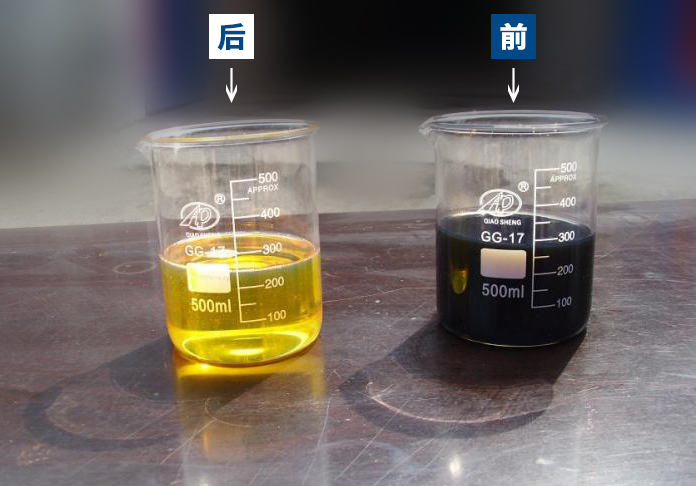

2、 Characteristics

This machine adopts the unique full bridge rectifier technology newly developed by our company (which is essentially different from all kinds of distillation technology in the world at present). Distillation is just a simple separation process of thermodistillation, which uses the different boiling points of the components in the liquid (solid) mixture to make the low boiling point components evaporate and then cool to separate, that is, a simple operation process of evaporation and cooling. A perfect combination of multistage differentiation of simple distillation is used to separate the components in the mixture by stages to achieve the specified highest purity. The gas phase and liquid phase are forced to flow reversely in the catalytic system in the multistage distillation differentiation process, so as to form vortex and enter into the refining tower. Then the principle of heat flow is used. The components in the mixture and liquid have different distillation ranges. In the process of contact with each other, the light components and heavy components in the liquid phase produce rectification, and the light components produce gas phase. The heavy components in the gas phase generate liquid phase, so as to realize the steady flow process of liquid mixture and achieve perfect separation. The gas is compressed and split, and then compressed to produce liquefied petroleum gas, so as to realize the full utilization of resources and zero pollution of the environment.

The device has the characteristics of continuous production, no pollutant, no chemical reagent, and fractional distillation.

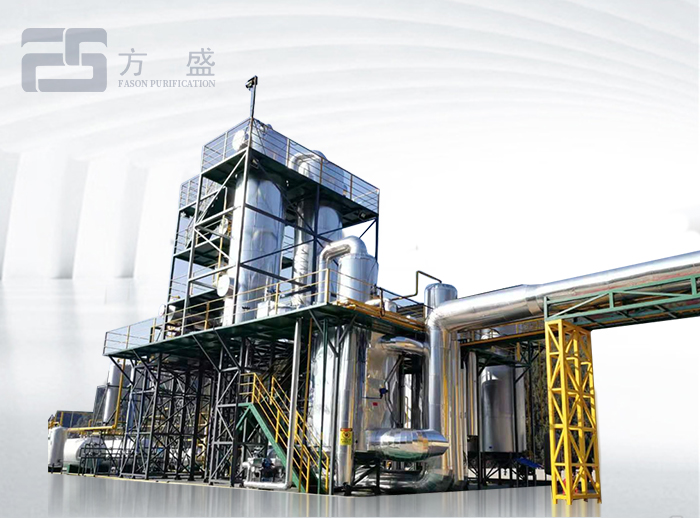

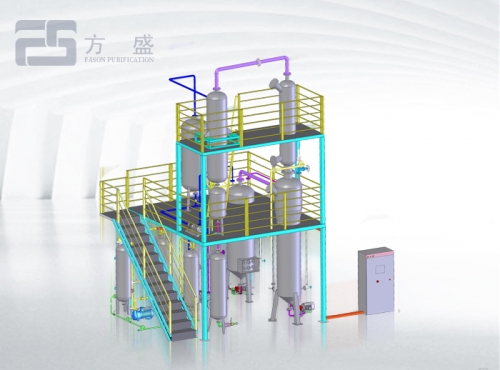

The main structure is divided into: primary distillation tower - Distillation Tower - heating system - vortex generator - rectification system - catalytic system - Distillation Tower - waste gas recycling system - cooling system - oil-water separation system - reflux system - vacuum system - liquid level control system - multi-channel temperature control system - residue treatment system - oil inlet and outlet device Stage pressure detection system electrical control system. The materials are all special materials, and the valves are made of wc9 material (safe, reliable, environment-friendly, energy-saving and durable).

3、 Technical parameter table

| Technical projects | Company | Model |

| FS-HDM-1 | FS-HDM-2 | FS-HDM-3 | FS-HDM-4 | FS-HDM-5 | FS-HDM-6 | FS-HDM-7 |

| Treatment capacity | L/h | 100 | 200 | 300 | 400 | 600 | 1000 | 2500 |

| Oil intake | L/min | 50 | 50 | 100 | 100 | 200 | 200 | 300 |

| Average power | Kw/h | 38 | 48 | 56 | 66 | 135 | 182 | 285 |

| Vacuum degree | Mpa | ≤-0.06~-0.09 |

| Working oil temperature | ℃ | 175-450 |

| Working negative pressure | MPa | ≤-0.082 |

| Voltage | V | 110/220/380/415 |

| Noise | db(A) | ≤80 |