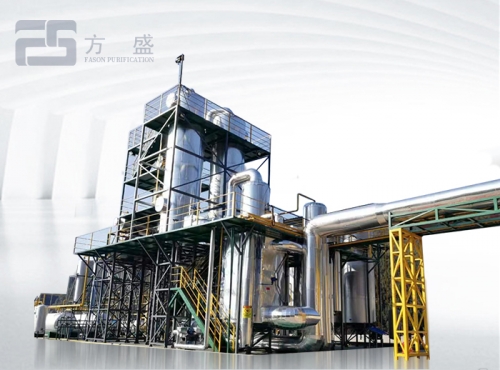

Centrifuge separator oil filter

The working principle is simple and the effect is remarkable. Inside it, there is a rotor with twin nozzle, which only needs the pressure generated by the oil to provide its driving force. After the equipment is opened, the oil in the tank is sent to the rotor through the pump. After the oil is filled with the rotor, the oil nozzle is sprayed along the lower part of the disc, which produces the driving force to make the rotor rotate at a high speed. Its speed can reach more than 4000-6000r.p.m, and the force produced is more than 2000 times of gravity, which is directly driven by the principle of centrifugal force to separate the impurities from the oil. Hard and sharp worn metal materials, coupled with the residual products that wear or deteriorate the oil, can be taken out of the size of 1 m. The impurities separated in the rotor are covered by impurities, and only need regular cleaning. In addition, as the proportion of water is larger than the oil, under the action of centrifugal force, the water from the oil is separated from the oil plate of the inner product of the rotor. It only needs to be cleaned in the cleaning process. The filtered oil flows directly through the gravity into the tank. The new molecular oil purifying machine also uses electrostatic separation and resin adsorption technology, which can remove the metamorphic oil molecules, make the insulating oil highly purified and improve the insulation performance.

Good use of oil filter

The vacuum oil filter is usually used for oil filtration in the workshop.

The vacuum oil filter is usually carried out in the workshop for oil filtration. Sometimes, in order to meet the requirements of construction, it is necessary to work on site. Our company has accumulated a great deal of experience in the field of oil filtration. The vacuum oil filter can be used in the field, and use the original oil equipment to make the oil storage tank, so that the hot oil circulate between the machine and the equipment, so that the oil and hot oil are circulate and dry at the same time. The design of oil and gas separation is improved and improved. The tube rotary fuel injector is installed with vacuum oil inlet, which reduces drag and has fast swirling speed. The plate and frame type oil filtration increases the effect of oil and gas separation. The vacuum oil filter is small in volume, light in weight, simple in structure and easy to operate. Oil filtration and oil filling for various oil immersed transformers, oil immersed current, voltage transformer and low oil relay are carried out. The hot oil circulating drying of all kinds of high and low pressure oil equipment in power plants, power stations, industrial and mining enterprises, petroleum, chemical and metallurgical units, especially for oil leaching current, voltage transformer and low oil circuit breaker is more effective. The vacuum oil filter is used to purify the slightly deteriorated transformer oil, so that its performance can meet the standards of oil use. It has the characteristics of small volume, light weight, convenient movement, low noise, long continuous working time, stable performance and convenient operation. It is used to filter the water and impurities in oil, turbine oil, hydraulic oil and so on. Filter paper is used as filter material.