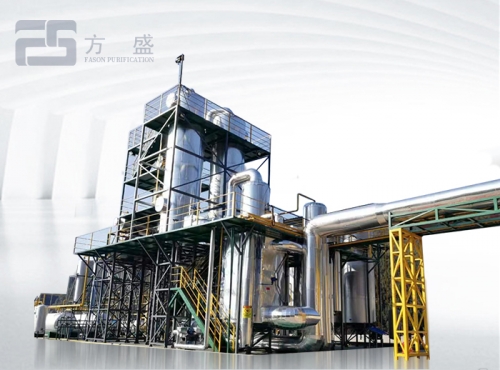

Use of insulating oil filter

Insulation oil filter - insulation oil filter use

It is used for regeneration and purification of insulating oil such as unqualified transformer oil, transformer oil, switch oil, and vacuum oil filling.

It is suitable for construction, installation, maintenance and on-site maintenance of UHV and UHV large transmission and transformation equipment above 110KV.

It is used for deep purification of high grade new oil, imported oil, mutual inductor oil and extra high voltage transformer oil.

It can also be used for deep dehydration treatment of oil products such as capacitor oil, air conditioning compressor, refrigerating oil and other oil products with low water content and low oil content.

The equipment has the functions of vacuum oil injection and vacuum pumping, which can meet the functions of vacuum drying, hot oil circulation and filtration in the construction site.

Because of the use of two stage high vacuum design, this series of models has a greater advantage in high altitude areas.

Four characteristics of insulating oil filter

Insulating oil polymer vacuum oil filter is mainly suitable for all kinds of low viscosity oil, that is, the purification of insulation oil such as high voltage transformer, current transformer, capacitor, circuit breaker, oil switch and so on. The equipment can be operated on line and electrified on deteriorating transformers, transformers and oil switches without interruption of power supply.

Characteristic:

1: insulating oil polymer vacuum oil filter. On the basis of the original vacuum oil filter, a greater improvement has been made. The multistage negative pressure filter horizontal structure is adopted. The performance of the bipolar vacuum is stable and advanced. The electrical design and installation are reliable, the appearance of the structure is compact and it is reasonable and novel.

Two: insulation oil purification cycle is short, low energy consumption, no filter paper and vulnerable materials, high degree of automation. Automatic control and protection device, light and flexible, low power consumption, low noise, easy operation, no filter core and traditional insulation oil treatment methods to reduce the cost by more than 90%.

Three: polymer composite filter material directly remove free carbon in power insulating oil. It can effectively guarantee the filtering accuracy of oil quality, that is, cleanliness, and automatic backwashing of filter equipment.

Four: the vacuum pump oil emulsion breaking circulation system and the vacuum circulating cooling device, water cooling and air cooling will switch at any time, thoroughly solve the malpractice of the freezing in the north of the north area which can not run normally in winter. The problem of oil emulsification is easy to eliminate in the long run of vacuum pump. It can be used stand-alone, and can also be used in conjunction with regeneration adsorption device.

Working process principle of vacuum oil filter

The transformer oil has been filtered through the filter filter of the DZJ vacuum oil filter, and the oil pump is pressurized by the oil pump. The filter is further filtered through the miscellaneous tank. Then, it enters the precision filter, the coalescence separation device and the regeneration device.

In the coalescence separation tank, the coalescence filter core and the oil water separation filter core are contained. After the oil passes through the agglomeration filter core made from the special material, the emulsified water and the free water in the oil are gathered by the water, most of which sink along the surface of the filter material, and a part of the smaller diameter particles enter the separation part and slide along the surface of the separation filter and precipitate. The water gradually subsids to the pool and can be discharged centrally. The coalescence separation of DZJ vacuum filter has a strong ability to divide water. By coalescence and separation, it also loosened the affinity between oil and water, which is conducive to deep dehydration.

The regeneration device

(1) has the functions of decolorization, regeneration and acidity reduction.

(2) the DZJ vacuum oil filter has the function of decolorization and deep water removal. There are no pressure measuring points or alarm points before and after each tank, and the filter element can be replaced according to the pressure difference. The device has no running time design components, and users can set the running time according to the need and stop automatically at that time. At this point, the system also has pressure control elements, differential display displays, and automatic bleeder valves.