1、 Scope of application

It is suitable for gear oil (open and closed) hydraulic oil, molding oil, gutter oil, track oil, compressor oil, vacuum pump oil, total loss system oil, axle oil, pneumatic tool oil, guide rail oil, bearing oil, turbine oil, etc. in petroleum, chemical, cement, metallurgy, mining, electric power, shipbuilding, machinery, military industry, rubber and plastic, instrument, transportation, building materials, papermaking and other industries Regeneration and purification of cylinder oil, drawing oil, conduction oil and transformer insulating oil (mineral oil and synthetic oil).

2、 DTS features

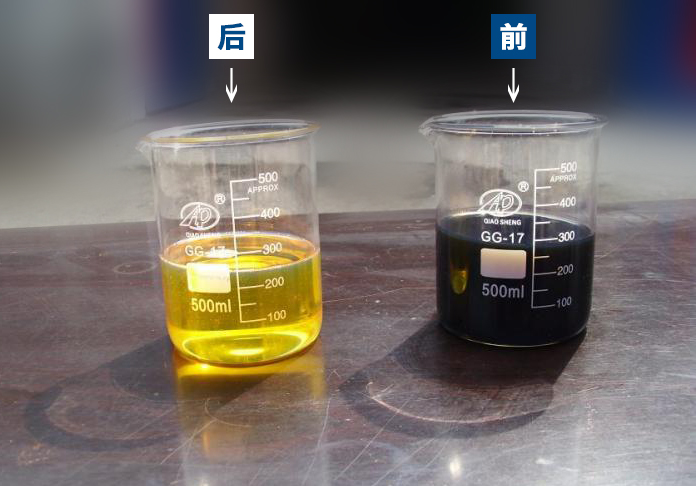

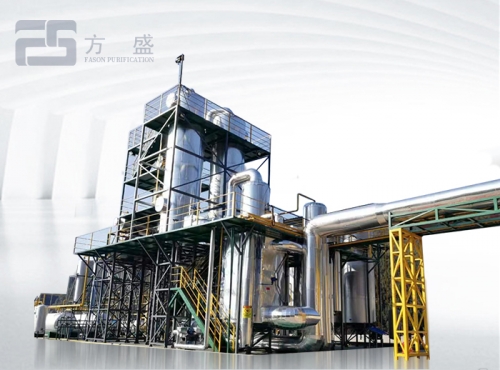

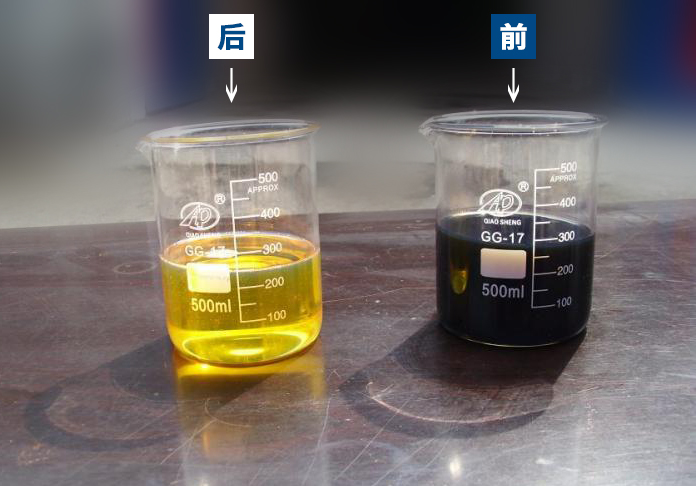

The equipment adopts the world's unique pure physical low-temperature distillation and microfiltration purification technology, which can quickly separate the water, oxides, metal impurities, carbon residue, gum, suspended solids, emulsions and other pollutants in the waste oil, and completely restore the physical and chemical indexes of the oil, such as viscosity, acid value, flash point and so on.

The special oil decolorization system can restore the color of black oil to transparent and transparent (except for non-standard oil, mixed oil and high temperature oil), without damaging the oil quality. The waste oil treated by the equipment can be used repeatedly as national standard oil.

Unique high-frequency electrostatic magnetic field purification system and medium specific gravity separation system, without any filter element, filter paper and other high-cost filtering consumables, not only has powerful purification function, but also can save a large amount of purchasing consumables for users.

The machine adopts five pump double temperature control technology, which completely avoids many problems caused by control failure; It is equipped with pipeline backwashing system, automatic feeding and slag discharging system and unique cooling system to make the operation of the equipment more stable and the operation and maintenance more convenient.

3、 Acceptance criteria

| Technical projects | Company | Standard |

| Kinematic viscosity | mm2/s | GB/T265 |

| Density | (20℃)kgm3 | GB/T1885 |

| Lightning | (Opening)℃ | GB/T3536 |

| Pour point | ℃ | GB/T3535 |

| Acid value | mgkOH/g | GB/T264Or4945 |

| Mechanical impurities | % | GB/T511 |

| Water content | Mark | GB/T0207Or260 |

| Colour | Chroma number | GB/T6540 |

| Demulsibility | 54℃ | GB/T7305 |

4、 Technical parameter table

| Technical projects | Company | Model |

| DTS-Ⅰ | DTS-Ⅱ | DTS-Ⅲ | DTS-Ⅳ |

| Rated heating power | Kw/h | 36 | 48 | 54 | 54 |

| Average power | Kw/h | 12 | 17 | 22 | 24 |

| Oil intake | L/min | 55 | 100 | 150 | 200 |

| Using power | V | 380(Or according to user requirements) |

| Working oil temperature | ℃ | 30~160 |

| Working pressure | MPa | ≤0.8 |

| Noise | db(A) | ≤70 |