Attention should be paid to the installation and commissioning of vacuum oil filter

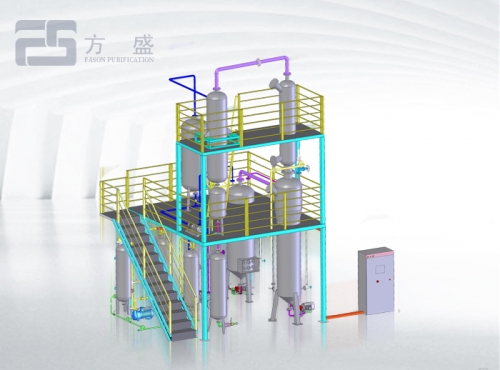

In recent years, the production of oil filter in China has developed rapidly. Various kinds of oil filter machines have played a role in machinery, mine, oil, chemical industry and other industries. The quality of the products is also the focus of attention.

You can choose the right type according to the condition of the oil you need to filter, and determine the size of the oil filter according to the amount of oil filtered.

In the installation of the vacuum oil filter, generally speaking, the oil filter machine produced in the large oil filter factory has been tested before the factory is out. Considering whether there will be any signs of loosening in the way of transportation, it is necessary to check whether the appliances and instruments are intact and the fasteners are loose after transportation to the site. The machine should be placed on the horizontal ground, and the user does not need to carry out the design and installation basis. The selection of the power line should be based on the total power of the oil filter to choose the maximum current to withstand.

In the debugging of the vacuum oil filter, generally speaking, the oil pipe of the oil filter is kept firm, the power line is connected correctly and the voltage is consistent. During the trial operation, shut down the drain valve and the air leakage valve connected with the outside, and carefully observe the display of the vacuum gauge.

In general, the vacuum oil filter in the factory, all the data will be set, the user can also be in accordance with their needs, in the adjustment of the corresponding changes, these are all need to be noticed.

How to ensure the service life of the oil filter

It may take a long time to run without interruption, or even a few years to stop maintenance, such as large nuclear power plants, power stations, steel production lines, etc. But the average time for the stopping of the oil filter is long, and many times may not be used for a long time. The interval of the two use may take a few months to open the machine. So this time we have to go and pay attention to the shutdown of the oil filter. This is directly related to the service life and operation performance of the oil filter.

The first is shutdown attention: turn off the order in turn, turn off the heater first (remember this must be the first to close), if not first shut the heater, may lead to air heating, may cause the machine to burn, and even seriously lead to leakage of electricity and other dangerous accidents. Second, after closing the heater, we need to keep the operation of the vacuum pump and the oil pump. When the oil is cooled to less than 50 degrees, the next operation is carried out, because the high temperature oil may have an adverse effect on the seal if it is stopped directly under the high oil temperature. Then close the vacuum pump, and the oil pump, and open the vent valve on the vacuum tank to remove the vacuum. Because of the low internal pressure, the oil in the machine can not be eliminated. When we remove the oil in the tank, we can take reasonable use of the oil pump and the opening and closing of the ball valves, and effectively eliminate the residual oil inside the machine. At the same time, we should note that if the machine is not suitable for a long time, we must completely remove the remaining oil inside the machine. Once again, the next boot can start smoothly, and will not pollute the nature of the oil when the next boot.

These are the precautions for the shutdown. Meanwhile, we need to pay attention to machine maintenance during downtime.

1. after long time use, we need to pay attention to check whether there are blackening phenomena in electrical equipment and lines, and find out problems in time.

2. after long term use, we should regularly replace the vacuum pump oil in the vacuum pump.

3. clean the filter element regularly or for a long time before using it, so as to prevent impurities from hardening and coking and blocking the filter element.

3. clean the condensate water every time to prevent water from corroding the body.

This is the point of attention to the shutdown of the oil filter. We must pay attention to routine maintenance, which is an important means to ensure the life and normal use of the machine.