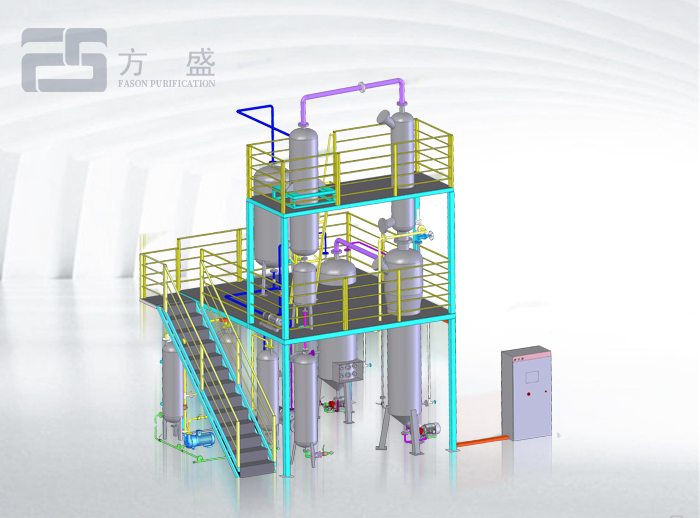

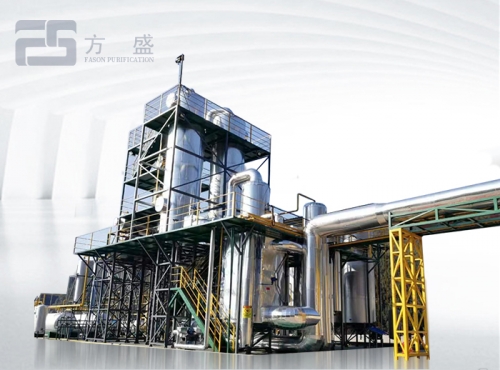

1、 Scope of application

Fs-wsl series is a water-soluble industrial waste liquid separation and purification device independently developed by our company according to customer demand (there is no similar product at present), which is suitable for mechanical processing, mold casting, forging, pulp and paper industry, etc. For example: petroleum, chemical industry, cement, steel, metallurgy, steel plant, electric power, shipbuilding, machinery, military industry, rubber and plastic, tire, auto parts, automobile, paint, instrument, transportation, building materials, paper making, food, pharmaceutical, textile and other industries

2、 Characteristics of aqueous solution

In various industrial manufacturing, due to the use requirements of products and different production processes, different oils and fluids will be used, such as emulsion for hot rolling process, cutting fluid for line cutting, flaw detection fluid (fluorescent agent, imaging agent, penetrant, cleaning agent, magnetic suspension, whose main chemical components are organic matter, alcohol, Sudan red, kerosene, acetone, titanium dioxide, alkane, ethanol, etc.) Most of these liquids are composed of water, and a small number of them are base oil, solubilizer dispersant, organic matter, vegetable oil, surface stabilizer, synthetic grease mixture, antirust additive, zinc naphthenate, sodium petroleum sulfonate (emulsion material), barium petroleum sulfonate, phenylpropanetriazole, monooleic acid, aluminum stearate, extreme pressure agent For the polar mixture of sulfur, phosphorus and chlorine, friction modifier and antioxidant, the density of general concentrated solution is less than 0.95, and the pH value of new solution is generally between 7-9.

Our company combined with more than 20 years of experience in various kinds of oil and liquid regeneration separation and purification technology, through repeated experimental demonstration, we have developed a complete set of solutions, which can separate the substances lower than, equal to, and higher than the boiling point of water. According to the different components contained in the waste liquid, the density, boiling point, hydrophilicity (attached materials), distillation range (initial boiling point, boiling point) of various chemical solutions are different Through repeated operation for 5 years, the rationality of equipment process, reliability of technology and stability of operation are further confirmed. After purification and separation, 3% - 8% of waste residue is discharged in small amount (water can be reused repeatedly), with high return on investment, saving water cost for enterprises (or direct discharge after simple filtration), Truly achieve the purpose of energy saving, emission reduction and efficiency for enterprises.

3、 Disadvantages of aqueous solution

It is easy to produce bacteria and mildew, which will make its active ingredients stink and deteriorate after chemical decomposition. If it is used overtime in order to save cost, it will seriously affect the product quality, the health of operators and the environment of the whole workshop.

4、 Treatment effect

COD:<500

Water: colorless and transparent

Note: if the emulsion contains detergent (the main component of the detergent is acetone), or contains light components such as gasoline and explosive oil, COD500 can be recycled to 99%, recyclable or discharged directly.