In the process of transportation, storage and use, the mechanical use of oil is often mixed with water and mechanical impurities, which has a certain effect on the performance and life of the mechanical equipment. Water on the metal surface will cause corrosion, in addition to the oil mixed with water, affect the performance of the oil, reduce the viscosity of the oil; mechanical impurities will wear the working surface, leave the surface of the work surface, and so on. The oil purifier is a device that can improve the insulation performance and the purity of the lubricating oil. It is divided into two types: mobile and fixed. The mobile equipment can be replaced by the need to replace the work place, and its Cardan wheel will help to make the equipment on a relatively narrow or uneven working site. The fixed structure is used for long - term non - moving sites.

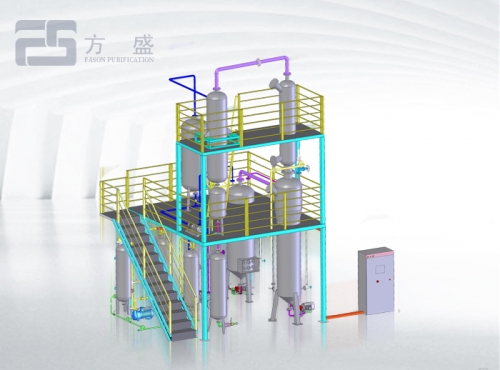

The oil purifying machine consists of the oil circuit system composed of filter, vacuum separator, oil pump and pipeline, the air system composed of cooler, condenser, storage tank, vacuum pump, demister, pipe and so on, electric control cabinet, pressure controller, electromagnetic valve and so on. It is used to filter all kinds of oil, hydraulic oil, machine tool cooling oil, lubricating oil, transformer oil, turbine oil and so on. A purifier can filter many kinds of oil without changing the filter paper, frame, filter element, oil tank and other devices. In theory, all kinds of oil can be processed by oil filter, but at present, the domestic technology of oil purification is uneven, so some oil products are difficult to deal with, so it is necessary to tailor them according to the actual situation of the users.

Chongqing Fangsheng purification equipment Co., Ltd. is one of the domestic technology powerful oil purifying machine manufacturers, can be customized according to customer needs, our production of oil purifying machine is widely used in power, chemical industry, printing and dyeing industry, is a good helper for you to maintain the equipment and prolong the life of the equipment.