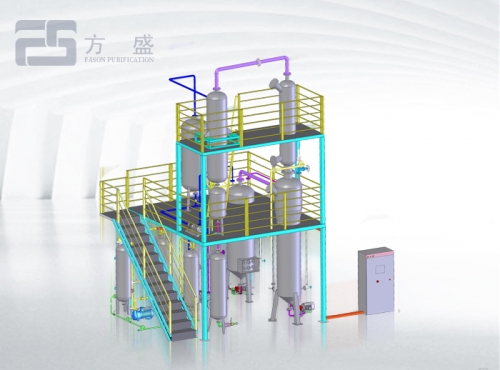

Oil filter can filter contaminants such as impurities and moisture in oil products. Oil filters should pay attention to cleaning and maintenance at ordinary times. Now let's explain how to filter the filter of oil filter.

1. filter filter for oil filter

The core part of the filter is the filter core. The filter consists of two parts: the filter frame and the stainless steel wire mesh. Among them, stainless steel wire mesh is suitable for damaged parts and should be carefully protected. If the stainless steel wire mesh is found to be deformed or damaged, it is necessary to replace it immediately.

When the filter filter works for a period of time, the filter core has precipitated a certain impurity, when the pressure drops, the flow rate will decrease, and the impurities in the filter core need to be removed in time. When cleaning impurities, special attention has been paid to the stainless steel wire mesh on the filter core that can not be deformed or damaged. Otherwise, the reinstalled filter, the purity of the filtered medium can not reach the design requirements, and the related equipment will be destroyed.

2. precision filter for oil filter

The core part of the precision filter is the filter element, and the filter element is also vulnerable. If the filter element is found to be deformed or damaged, it needs to be replaced immediately.

When the precision filter works for a period of time, the filter core will intercept a large amount of impurities, when the pressure drops, the flow rate will decrease, the impurities in the filter should be cleared in time, and the filter core should be cleaned at the same time. When removing impurities, special attention should be paid to precision filter elements, which should not be deformed or damaged. In addition, some precision filter elements can not be used repeatedly, pay special attention.

The above is the filter cleaning and maintenance method. Only when we maintain the oil filter well, can the oil filter work normally and stably.